Headquartered in Lohr am Main, Bosch Rexroth is a leading producer of hydraulic pumps. Rexroth hydraulic pumps are known for their reliability, energy efficiency and ability to work flawlessly in testing conditions. Made from quality materials, they are built to last. Their advanced control options such as electro hydraulic and proportional controls allow operators to precisely control flow and pressure.

Types of Rexroth Hydraulic Pumps

Here are some different types of Rexroth hydraulic pumps

Vane Pumps

Rexroth vane pumps are notably quieter than pumps by other manufacturers in their category. Their advanced design results in lower pulsation levels. Low hysteresis with high repetition accuracy helps ensure better control.

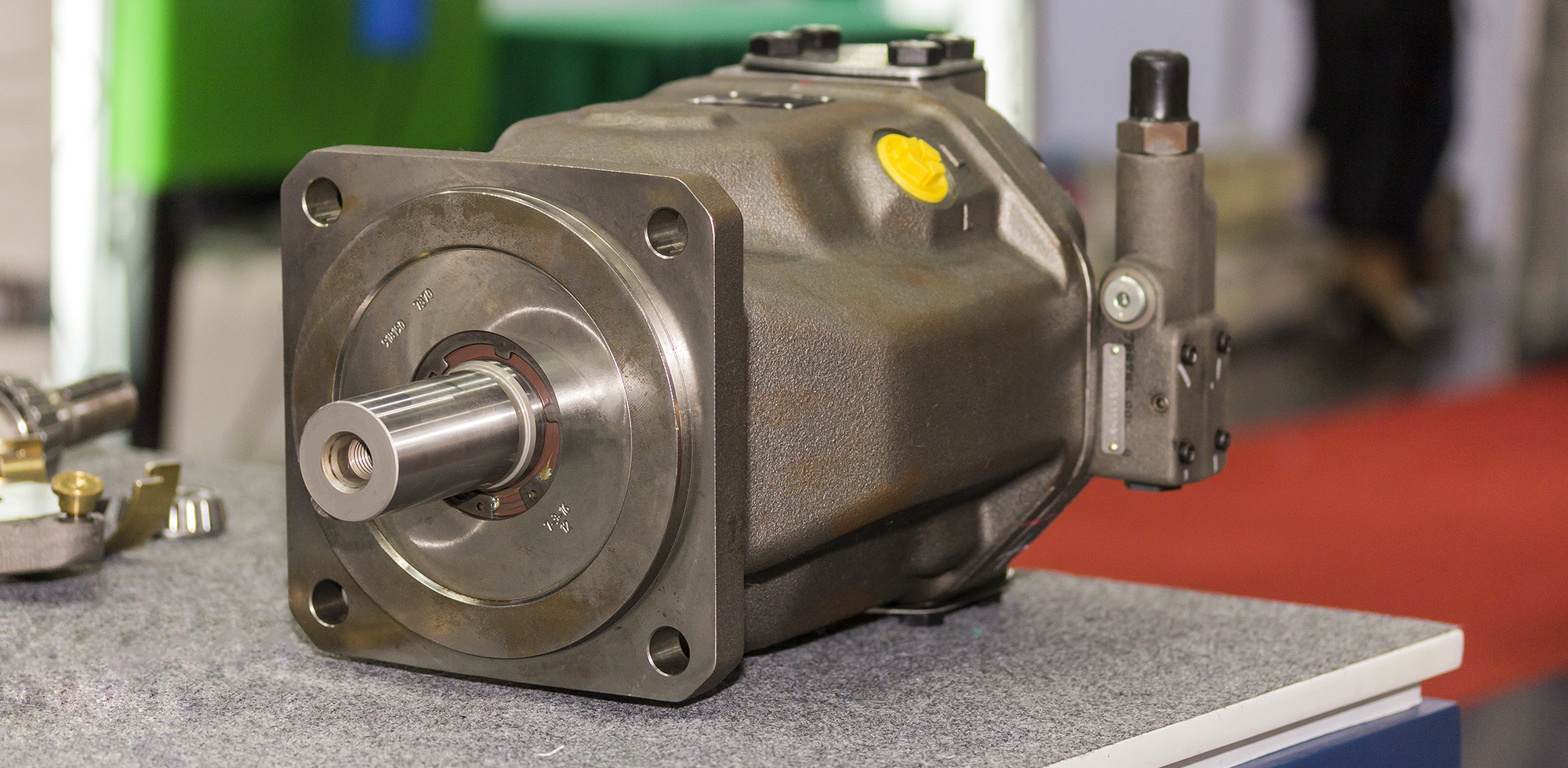

Axial Piston Pumps

Rexroth offers a range of axial piston pumps in different configurations (both in open and closed circuits) to meet specific needs. Versatile axial piston pumps by Rexroth are used in various industries including agriculture, construction, and mining.

External Gear Pumps

External gear pumps by Rexroth feature a simple, yet robust design. These pumps are ideal for low pressure applications

Benefits of Rexroth hydraulic pumps

Here are some things that make Rexroth hydraulic pumps popular.

Noise Reduction

Top of the line Rexroth hydraulic pumps utilize noise reduction technology and are much quieter than hydraulic pumps by other manufacturers. They are fit for use in environments where noise is a concern.

Pressure Capabilities

Rexroth hydraulic pumps can operate at pressures exceeding 500 psi. Some models can operate up to a pressure of 7,250 psi making them the preferred choice for heavy duty applications.

Durability

Rexroth hydraulic pumps utilize quality materials. They are capable of working in extreme temperatures and handling heavy loads.

Innovative Technology

Bosch Rexroth invests heavily in R & D. Rexroth hydraulic pumps utilize IOT and other latest technologies that improve their performance and efficiency.

Modular Design

Modular Rexroth hydraulic pumps can be easily integrated with complex systems, which makes them ideal for a range of applications. Different types of control options including mechanical and electronic adjustments can be used for modular pumps.

Global Support

Bosch Rexroth has business operations all over the world. The manufacturer offers exceptional customer support and has a strong distribution network. Because Rexroth hydraulic pump parts are readily available, it’s easier to maintain and service Rexroth pumps.

Rexroth Hydraulic Pump Maintenance Tips

Follow these tips to keep your Rexroth hydraulic pump in good working order.

- Use the right hydraulic oil recommended by the manufacturer. Periodically check fluid levels and top up as required

- Clean or replace filters regularly

- Check the suction line and make sure air does not enter the system

- Inspect pump components including gaskets, seals, and the pump housing for signs of damage

Hydraulic.net is a reliable supplier of replacement Rexroth hydraulic pumps. Our affordable replacement pumps perform flawlessly in testing conditions. To discuss your requirements with our team, call (630) 543-7630.