A gear pump is a type of positive displacement pump. It consists of two interlocking meshed gears to pump fluids. Gear pumps are used in several industries, including chemical and petrochemical industries, to handle various types of oils and viscous liquids. They feature a simple and compact design, are durable, and can pump liquids at high pressures.

How Does a Gear Pump Work?

As the gears of a pump rotate, the fluid on the inlet side gets trapped in their teeth and the walls of the casing. The trapped fluid is then moved to the outlet. The meshing displaces the fluid, forcing it out of the discharge port. A suction is created at the inlet, and pressure is generated at the outlet to effectively move the fluid through the pump. Close clearances between the gears and casing prevent the fluid from leaking back from the discharge side to the suction side.

Types of Gear Pumps

Here are some popular types of gear pumps.

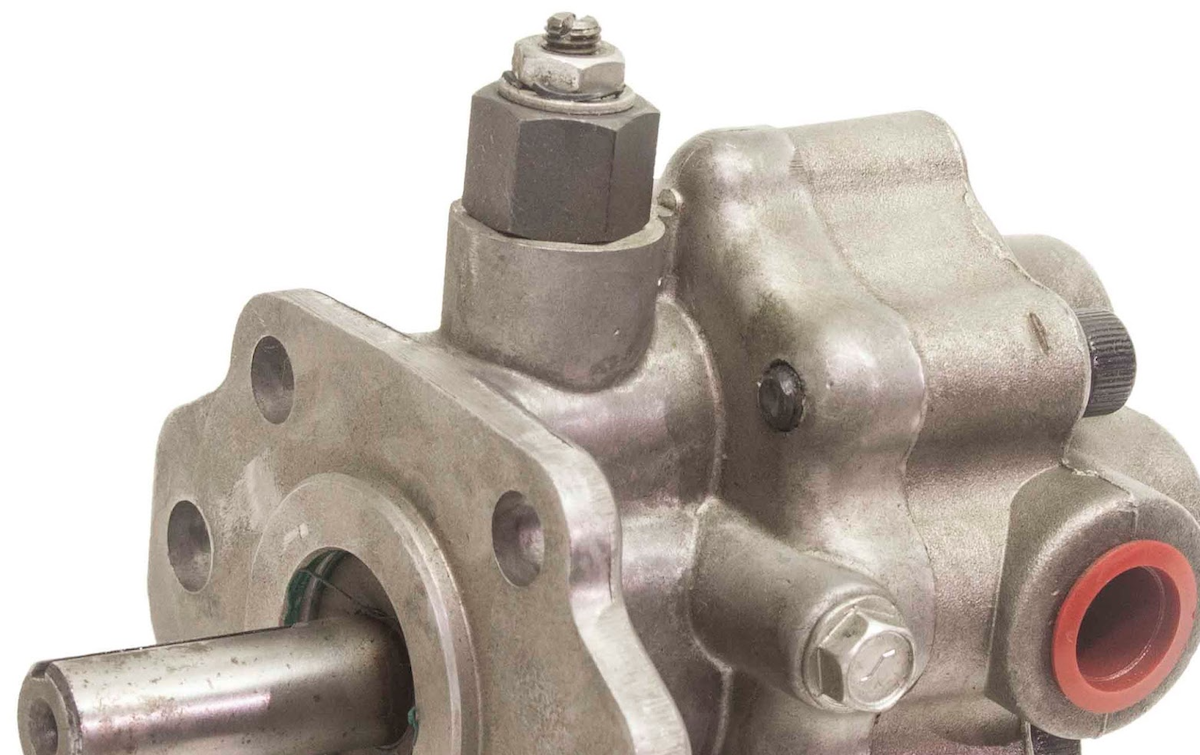

External Gear Pumps

An external gear pump uses two gear pumps supported by separate shafts. Usually, one gear is driven by a motor, and it drives the other motor. In some cases, both shafts are driven by motors. There are two types of external gear pumps – helical gear pumps and herringbone gear pumps. As the name suggests, a helical gear pump has helical gears and is quieter than spur gears. Herringbone gear pumps utilize two sets of helical gears. Their unique design (there is no gap between the sets) helps reduce noise and pulsation.

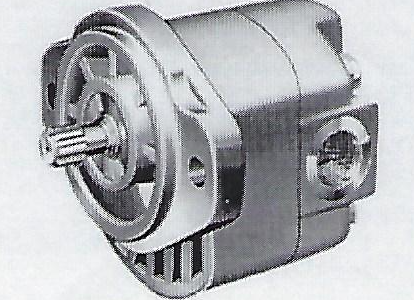

Internal Gear Pumps

An internal gear pump consists of a large external gear or rotor and a smaller internal gear or idler. One of the most widely used types of internal gear pump is the gerotor pump. The rotors of a gerotor pump rotate to create an expanding pocket. As the pocket contracts, fluid is drawn in through the inlet and forced out through the outlet.

How Efficient Are Gear Pumps?

Gear pumps are known for their ability to maintain a consistent flow rate. Their volumetric efficiency usually ranges from 90 to 98 per cent. The design of a gear pump minimizes the internal slippage of fluid. Gear pumps also have a high mechanical efficiency (usually between 85% and 95%). The higher the mechanical efficiency of a Rexroth hydraulic pump, the lesser the amount of energy lost due to friction or other mechanical factors during the conversion of mechanical energy into hydraulic energy. The overall efficiency (a product of volumetric efficiency and mechanical efficiency) of gear pumps ranges from 70% to 90%.

Applications

Gear pumps are used in:

- Chemical, petrochemical, and manufacturing industries to pump a wide variety of viscous and corrosive chemicals, liquids, and petrochemicals.

- The oil and gas industry to move fuel, crude oil, and lubricating oils.

- The polymer industry to pump high-viscosity fluids.

Hydraulic.net is a renowned supplier of hydraulic pumps. Manufactured in a state-of-the-art facility, our pumps meet high quality standards. To learn more, call (630) 543-7630.