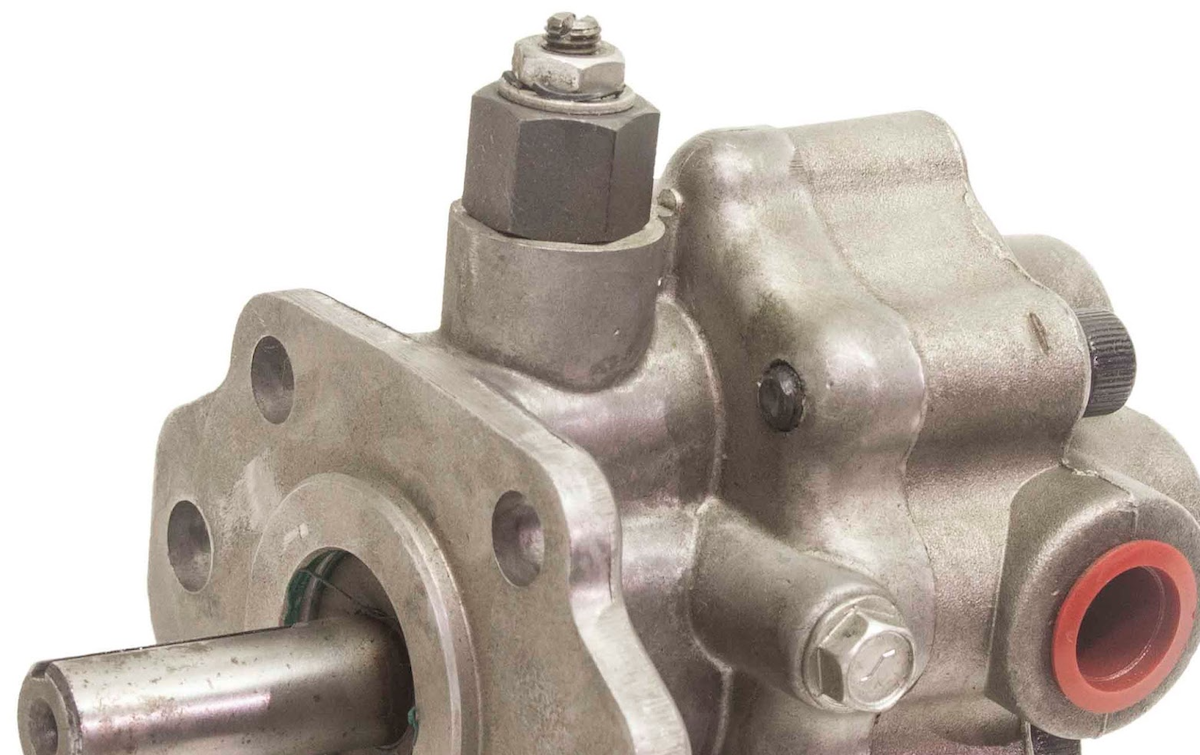

A hydraulic gear pump is designed to convert mechanical energy into hydraulic energy. They are used in many applications like braking systems, hydraulic systems, fan drive cooling and transmission systems.

Though durable, hydraulic pumps generally don’t last a lifetime. On average, a well maintained hydraulic pump can last 6k-10k hours of operation depending on a number of factors such as pump type, operating conditions, and how frequently the pump runs at its full capacity. If your hydraulic pump is very old or a hydraulic pump repair cost is more than 50% of the market value of the pump, it should be replaced.

Causes of Hydraulic Pump Failure

Before replacing a hydraulic pump try to deter the cause of failure. An internal inspection of the internal components will generally tell the story.

Mechanical Failure

Over pressurized

If a hydraulic gear pump is exposed to higher pressures than it is designed for you will see wear at the bushing and gear tips, usually inside the gear housing too.

Contaminated Fluid

Contaminants such as dirt particles and metal shavings can wear internal components of a hydraulic gear pump faster, leading to premature failure.

Hydraulic Pump Replacement Tips

The wrong hydraulic pump can affect the performance of your hydraulic system or reduce its lifespan. When choosing a replacement pump, consider the flow and pressure specifications provided by the system manufacturer. This is a service Hydraulic.Net provides on every order.

Clean the System

Clean the hydraulic system thoroughly before installing a new pump. Insure the hydraulic fluid is free of contaminants. Replace the filters to prevent dirt from entering the new pump. Use the quality hydraulic fluid, remember cheap recycled hydraulic oil will significantly reduce the life of your hydraulic system.

The right pump for your machine

Hydraulic.net offers a range of hydraulic pumps designed to meet diverse needs. Manufactured in a state-of-the-art facility, our pumps are built to last. To learn more, call (630) 543-7630.

Characteristics of Hydraulic.Net ,Inc Hydraulic Pumps

Headquartered in Saint Augustine Florida Hydraulic.Net , Inc produce a wide variety special application hydraulic pumps. It’s focus has been producing pumps for OEM service replacement demand when the original manufacturer ends their production. Our pumps known for their reliability, energy efficiency and ability to work flawlessly in testing conditions. Made from quality materials, they are built to last. Their pump line up includes control options such as electro hydraulic and proportional controls allow operators to precisely control flow and pressure.

Benefits of Rexroth hydraulic pumps

Here are some things that make Hydraulic.Net ,Inc hydraulic pumps popular.

Durability

These special application hydraulic pumps utilize quality materials. They are capable of working in extreme temperatures and handling heavy loads and meet all the form, fit and functionality of the original OEM pumps.

Global Support

Hydraulic.net ,Inc operations ships pumps all over the world. The manufacturer offers exceptional customer support.

Gear Hydraulic Pump Maintenance Tips

- Follow these tips to keep your Rexroth hydraulic pump in good working order.

- Use the right hydraulic oil recommended by the manufacturer. Periodically check fluid levels and top up as required

- Clean or replace filters regularly

- Check the suction line and make sure air does not enter the system

- Inspect pump components including gaskets, seals, and the pump housing for signs of damage

Hydraulic.net is a reliable supplier of replacement special application hydraulic pumps. Our affordable replacement pumps perform flawlessly in testing conditions. To discuss your requirements with our team, call (630) 543-7630.