Cessna hydraulic pumps are used in aircraft, ground support equipment at airports (such as vehicles used for towing aircraft), material handling systems, and boat steering systems. They are durable, low maintenance, and can operate in the harshest work environments.

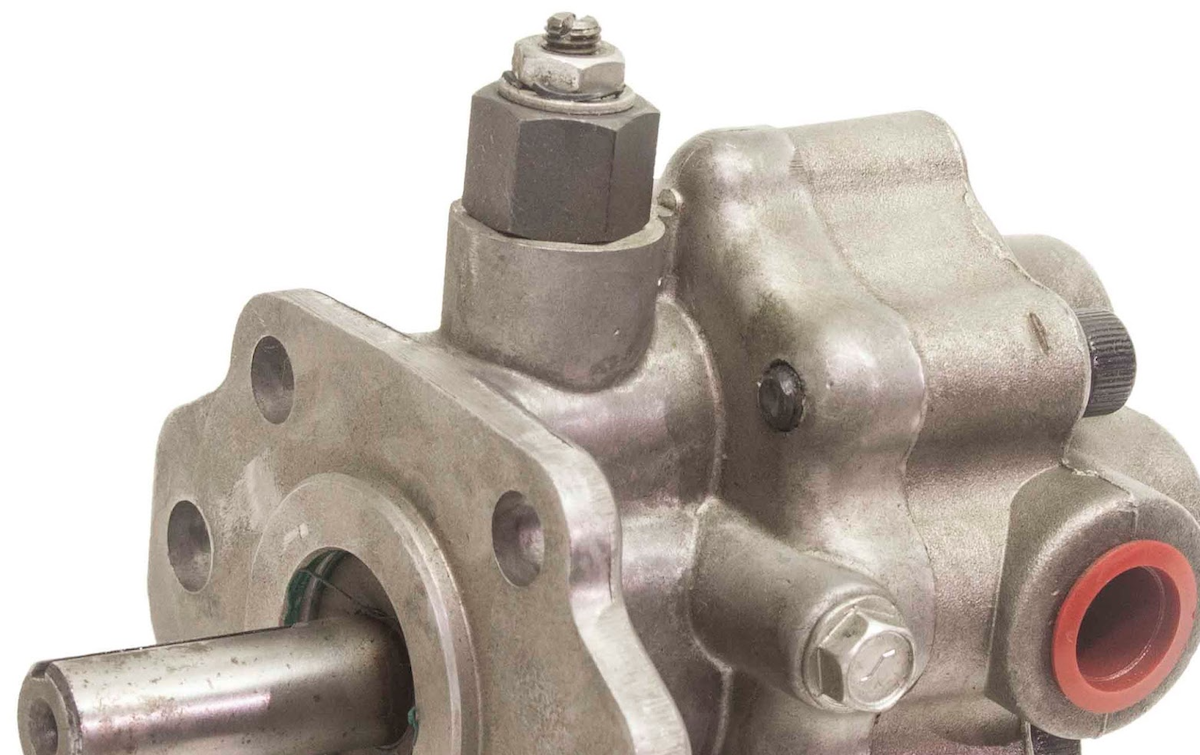

Here are the main components of a Cessna hydraulic pump.

Pump Housing

It encloses and supports the internal components of the pump. Pump housing is usually made of a durable metal that can withstand high pressures exerted during operation.

Inlet and Outlet Ports

These are the pathways through which hydraulic fluid enters and leaves the pump. The inlet port draws hydraulic fluid from the reservoir into the pump. Pressurized fluid is forced out through the outlet port.

Gears or Pistons

A gear pump utilizes a set of interlocking gears, whereas a piston pump uses a series of pistons to pressurize hydraulic fluid.

Pressure Relief Valve

To prevent damage, keep the pressure within the specified range. When the pressure gets too high, the pressure relief valve opens to release some of the hydraulic fluid back into the reservoir or a bypass line.

Pump Drive Gear

This connects the pump to the aircraft’s engine or electric motor, transferring mechanical energy (required to move internal pump components) to the hydraulic pump.

Seals and Gaskets

These prevent leaks and maintain the optimum pressure. They seal the gaps between the parts of the pump.

Bearings

They help reduce friction between pump parts and wear and tear on the pump.

Control Valves

Some hydraulic pumps have control valves that help regulate the flow of hydraulic fluid.

Tips to Maintain Cessna Hydraulic Pumps

Cessna hydraulic pump maintenance is a matter of necessity rather than choice. Regular maintenance prevents costly problems and keeps your Cessna hydraulic pump working at its peak efficiency.

Here are some tips to help you keep your Cessna hydraulic pump in good working order.

Perform Regular Inspections

Periodically inspect hoses, fittings, and connections for signs of leaks and damage. Fix any problems immediately to prevent them from snowballing into major issues.

Maintain Proper Hydraulic Fluid Levels

Periodically check hydraulic fluid levels and top up if required. When replacing hydraulic fluid, follow the manufacturer’s instructions. Use the type of fluid suggested by the manufacturer.

Clean the System

Dirt and debris can contaminate hydraulic fluid. Cleaning your Cessna hydraulic pump regularly is a great way to prevent contamination. Follow these steps to clean your pump.

- Turn off and depressurize the pump.

- Drain hydraulic fluid and wipe down the external surface with a clean cloth.

- Remove and clean/replace filters.

- Clean internal parts with a solvent.

- Flush the system with a flushing fluid to remove the remaining contaminants.

- Reassemble the pump and add hydraulic fluid.

Remove Air Pockets

If air gets trapped within your hydraulic pump, it can affect the pump’s efficiency. Bleed your pump regularly to remove air pockets.

Hydraulic.net has a large collection of Cessna hydraulic pumps. No matter how complex the intended application is, we will have the right hydraulic pump for it. To discuss your requirements with our team, call (630) 543-7630.