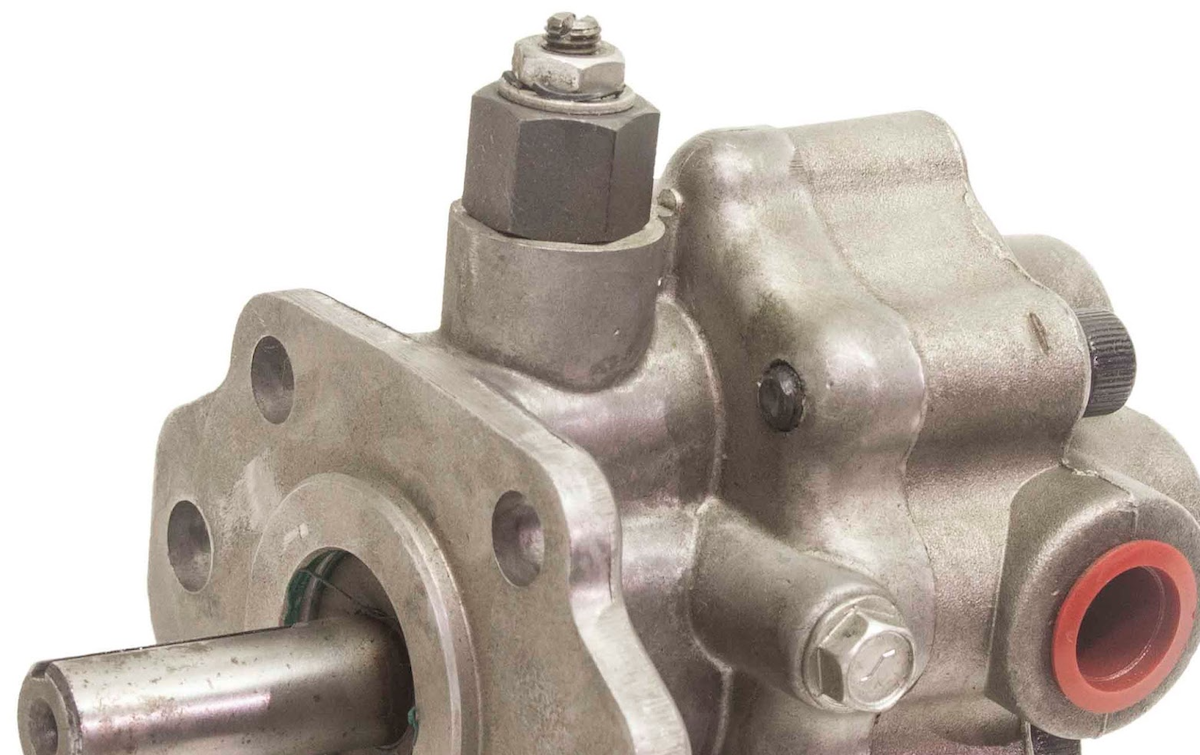

Haldex Barnes hydraulic pumps are known for their durability and efficiency. That said they are machines at the end of the day, and like other machines can develop problems. A failing Barnes hydraulic pump is extremely inefficient and can lead to delays and affect overall productivity. If your hydraulic pump fails completely, it may cause the system to shutdown.

Here are some signs your Barnes hydraulic pump is failing and needs immediate repair.

Reduced Efficiency and a Drop in Performance

If your Haldex Barnes hydraulic pump seems slower (as a result the mechanism its power slows down) than usual or does not generate enough pressure, its components may have started to wear out.

Unusual Noises

Weird hissing, grinding or screeching noises coming from a hydraulic pump can indicate aeration or cavitation. These sounds can be caused by worn out gears of bearings. If you are hearing unusual noises as your hydraulic pump runs, it may be struggling to maintain proper fluid flow.

Overheating

Increased friction between worn out hydraulic pump components can cause overheating. Some other common causes of overheating include contaminated hydraulic fluid, low levels of reservoir fluid, and blocked heat exchanger. Overheating can not only affect system performance, but also cause pump components to wear out faster. If your hydraulic pump overheats while running, immediately stop it and try to diagnose the problem.

Fluid Leaks

Leaking hydraulic fluid is a sign of an underlying problem such as worn seals or cracks in the pump casing.If your pump is leaking hydraulic fluid, it could lose pressure. Pressure loss can affect the pump’s overall efficiency.

Vibrations

If your hydraulic pump vibrates excessively, its bearings may have worn out or the pump propellers are imbalanced. Do not ignore the problem and have an expert inspect your Haldex Barnes hydraulic pump as soon as possible.

Contaminated Fluid

Contaminated hydraulic fluid can cause serious, in some cases irreversible damage to a hydraulic pump. If you notice hydraulic fluid discoloration or small particles floating in the fluid, consult a professional.

Hydraulic Pump Maintenance Tips

Hydraulic pump maintenance is a matter of necessity, rather than choice. Regular hydraulic pump maintenance nips pump problems in the bud, helping keep your Haldex Barnes hydraulic pump in good working order. Well-maintained hydraulic pumps are more efficient, reliable, and cost less to operate.

Follow these tips to maintain your hydraulic pump.

- Change hydraulic fluid at manufacturer recommended intervals

- Use filters to keep contaminants out of hydraulic fluid. Replace clogged and dirty filters in a timely manner and maintain proper hydraulic fluid levels

- Periodically inspect hoses, fittings, and connections for leaks

- Make sure pump and drive components are aligned properly

- Use high-quality (genuine) replacement parts

Hydraulic.net offers a range of hydraulic pumps by leading manufacturers at an affordable price. Our hydraulic pumps meet stringent quality standards and are a cut above the rest. To learn more, call (630) 543-7630.